US NAVY SCUBA DIVING & UNDERWATER WELDING MANUALs 1200pgs gas arc weld & salvage

Item Description

Item Details

Item Description

1970 70 1971 71 mopar dodge chrysler imperial

THE U.S. NAVY DIVING MANUAL

AND

THE U.S. NAVY UNDERWATER WELDING MANUAL

----------------------------------------

Nearly 1200 PAGES OF DIVING DIAGRAMS AND DATA! Don't confuse this manual with smaller ones...This one is the COMPLETE 1200 page version !

This Covers nearly ALL aspects of Recreational and Commercial Diving and offers a wealth of information from the true Pros of the Business

The U.S. Navy Diving Manual CD contains all 5 volumes covering Scuba, Air, Mixed Gas, Re-Breathers, Chamber Operations, Equipment, Dive Medicine, and all the Decompression Tables.

- Vol. 1: Diving Principles and Policies

- Vol. 2: Air Diving Operations

- Vol. 3: Mixed-Gas Surface-Supplied Diving Operations

- Vol. 4: Closed-Circuit and Semi-closed Circuit Diving Operations

- Vol. 5: Diving Medicine & Recompression Chamber Operations

* WE SHIP WORLDWIDE TO: ENGLAND, SWEDEN, DENMARK, THE NETHERLANDS, CANADA, AUSTRALIA AND ALL OF EUROPE ! (see shipping rates below)

THE

U.S. Navy Underwater Welding and Cutting Manual

This CD contains:

TABLE OF CONTENTS

FOREWARD....................................................................................................................... i

TABLE OF CONTENTS................................................................................................... iii

LIST OF ILLUSTRATIONS............................................................................................. ixv

LIST OF TABLES............................................................................................................. xi

STANDARD NAVY SYNTAX SUMMARY ................................................................ xiii

SAFETY SUMMARY.......................................................................................................xvvv

CHAPTER (1).......... INTRODUCTION

1-1 SCOPE........................................................................................................... 1-1

1-2 UNDERWATER CUTTING OVERVIEW................................................... 1-1

1-3 UNDERWATER WELDING OVERVIEW ................................................. 1-2

CHAPTER (2)..........UNDERWATER CUTTING

2-1 INTRODUCTION ......................................................................................... 2-1

2-2 OXYGEN-ARC CUTTING .......................................................................... 2-2

2-2.1 Principles of Operation .................................................................................. 2-2

2-2.2 Steel-Tubular Electrodes................................................................................ 2-2

2-2.2.1 Advantages of the Steel-Tubular Electrodes ................................................. 2-5

2-2.2.2 Disadvantages of the Steel-Tubular Electrode............................................... 2-5

2-2.3 Electrode Amperage Requirements ............................................................... 2-5

2-2.4 Oxygen Requirements.................................................................................... 2-6

2-2.5 Material Consumption ................................................................................... 2-6

2-2.6 Oxygen Pressure ............................................................................................ 2-6

2-2.7 Oxygen Purity .............................................................................................. 2-11

2-2.8 Grounding the Work .................................................................................... 2-11

2-2.9 Steel-Tubular Electrode Cutting Technique (Thick plate) .......................... 2-11

2-2.10 Steel-Tubular Electrode Cutting Technique (Thin plate) ............................ 2-15

2-2.11 Piercing Holes in Steel Plate........................................................................ 2-15

2-2.12 Steel-Tubular Electrode Cutting Technique (Cast Iron and Non-Ferrous Metals) ......................................................................................................... 2-18

2-2.13 Post-dive Maintenance................................................................................. 2-18

2-3 EXOTHERMIC ELECTRODES................................................................. 2-22

2-3.1 Electrode Amperage Requirements ............................................................. 2-22

2-3.2 Oxygen Requirements.................................................................................. 2-25

2-3.3 Material Consumption ................................................................................. 2-25

2-3.4 Advantages and Disadvantages of the Exothermic Electrode Cutting Process ......................................................................................................... 2-25

2-3.4.1 Disadvantages of Exothermic Electrodes .................................................... 2-27

2-3.5 Grounding the Work .................................................................................... 2-27

2-3.6 Exothermic Cutting Technique .................................................................... 2-28

2-3.6.1 Exothermic Cutting Technique (Cast Iron, Stainless Steel and Non-Ferrous Metals).................................................................................... 2-30

2-3.6.2 Exothermic Cutting Technique (Concrete, Rock and other Non-Conductive Materials) ......................................................................... 2-31

2-3.6.3 Exothermic Hole Piercing............................................................................ 2-31

2-3.7 Trouble Shooting.......................................................................................... 2-31

2-3.7.1 Symptoms .................................................................................................... 2-31

2-3.7.2 Probable Causes........................................................................................... 2-32

2-3.7.3 Locating and Solving the Problem............................................................... 2-32

2-3.8 Post-Dive Maintenance................................................................................ 2-33

2-4 SEELER ENTERPRISES LU-001 EXOTHERMIC CUTTING TOOL (KERIE CABLE)........................................................... 2-33

2-4.1 Advantages and Disadvantages of the of the Kerie Cable........................... 2-34

2-4.2 Materials Required for Kerie Cable Cutting................................................ 2-35

2-4.3 Equipment Set-up ........................................................................................ 2-37

2-4.4 Kerie Cable Preparation............................................................................... 2-39

2-4.5 Cutting Underwater...................................................................................... 2-39

2-4.6 Cutting Technique........................................................................................ 2-40

2-4.7 Cutting Thin Metals ..................................................................................... 2-40

2-4.8 Cutting Thick Metals ................................................................................... 2-41

2-4.9 Re-Lighting Cable Underwater.................................................................... 2-43

2-4.10 Emergency Off Safety Procedures............................................................... 2-43

2-4.11 Loss of Communications ............................................................................. 2-43

2-4.12 Equipment Tender........................................................................................ 2-43

2-4.13 Electrical Precautions .................................................................................. 2-43

2-4.14 Post-Dive Maintenance................................................................................ 2-43

2-5 SHIELDED METAL ARC CUTTING........................................................ 2-44

2-5.1 Principles of Operation ................................................................................ 2-44

2-5.2 Materials ...................................................................................................... 2-44

2-5.3 Waterproofing Electrodes ............................................................................ 2-44

2-5.4 Underwater Shielded Metal-Arc Cutting Techniques.................................. 2-45

2-5.5 Drag Technique............................................................................................ 2-46

2-6 CONCLUSION............................................................................................ 2-46

CHAPTER (3).......... UNDERWATER WELDING

3-1 INTRODUCTION ......................................................................................... 3-1

3-2 MECHANICAL BARRIERS ........................................................................ 3-2

3-2.1 Cofferdams and Caissons............................................................................... 3-2

3-2.2 Mini-Habitats ................................................................................................. 3-2

3-3 SHIELDED METAL-ARC WELDING ........................................................ 3-3

3-4 WET WELDING ........................................................................................... 3-3

3-5 SHIPBUILDING MATERIALS.................................................................... 3-3

3-6 MATERIALS USED IN UNDERWATER SHIELDED METAL-ARC WELDING..................................................................................................... 3-6

3-6.1 Underwater Shielded Metal-Arc Welding Electrodes ................................... 3-6

3-6.2 Tong Test Ammeter ....................................................................................... 3-6

3-6.3 Electrode Polarity .......................................................................................... 3-6

3-7 UNDERWATER WELDING ARCS ............................................................ 3-8

3-8 CONDITIONS ADVERSE TO UNDERWATER WELDING..................... 3-8

3-9 STRENGTH OF UNDERWATER FILLET WELDS ................................ 3-10

3-9.1 Parts of a Weld (Definitions) ....................................................................... 3-10

3-9.2 Fillet Weld ................................................................................................... 3-12

3-9.3 Trial Weld .................................................................................................... 3-12

3-10 SURFACE CLEANING.............................................................................. 3-12

3-11 JOINT FIT-UP............................................................................................. 3-13

3-12 UNDERWATER SHIELDED METAL-ARC WELDING TECHNIQUES ............................................................................................ 3-13

3-12.1 Welding Set-Up Procedures......................................................................... 3-13

3-12.2 Self-Consuming Technique ......................................................................... 3-14

3-12.3 Fillet Welding in the Horizontal Position (Self-Consuming Technique) .... 3-14

3-12.3.1 Fillet Welding in the Vertical Position ........................................................ 3-17

3-12.3.2 Fillet Welding in the Overhead Position...................................................... 3-17

3-12.3.3 Self-Consuming and Manipulative Techniques........................................... 3-20

3-12.3.4 Fillet Welding Where There is Poor Fit-Up ................................................ 3-20

3-12.4 Welding on Thin Plates................................................................................ 3-20

3-13 PROCEDURE FOR REPAIRING SMALL CRACKS............................... 3-22

3-13.1 Using a Rectangular Patch ........................................................................... 3-22

3-13.2 Using a Circular Patch ................................................................................. 3-22

3-14 POST-DIVE MAINTENANCE .................................................................. 3-25

CHAPTER (4).......... UNDERWATER ARC CUTTING AND WELDING EQUIPMENT

4-1 INTRODUCTION ......................................................................................... 4-1

4-2 EQUIPMENT USED FOR UNDERWATER ARC CUTTING AND WELDING ........................................................................................... 4-1

4-2.1 Oxygen-Arc and Shielded Metal-Arc Equipment ......................................... 4-1

4-2.2 Diving Equipment.......................................................................................... 4-1

4-2.2.1 Welding Shields............................................................................................. 4-1

4-2.3 Power Supply Requirements.......................................................................... 4-9

4-2.3.1 Power Converters........................................................................................... 4-9

4-2.3.2 Welding Generator, Pre-Setup Inspection ................................................... 4-11

4-2.3.3 Polarity......................................................................................................... 4-11

4-2.3.4 Polarity test .................................................................................................. 4-11

4-2.3.5 Tong Test Ammeter ..................................................................................... 4-13

4-2.3.6 Amperage and Voltage ................................................................................ 4-13

4-2.3.7 Diesel Driven Welding Generator Amperage and Voltage Settings ........... 4-15

4-2.4 Safety Switches............................................................................................ 4-16

4-2.5 Power Cables and Connectors ..................................................................... 4-16

4-2.6 Gas Manifolds.............................................................................................. 4-17

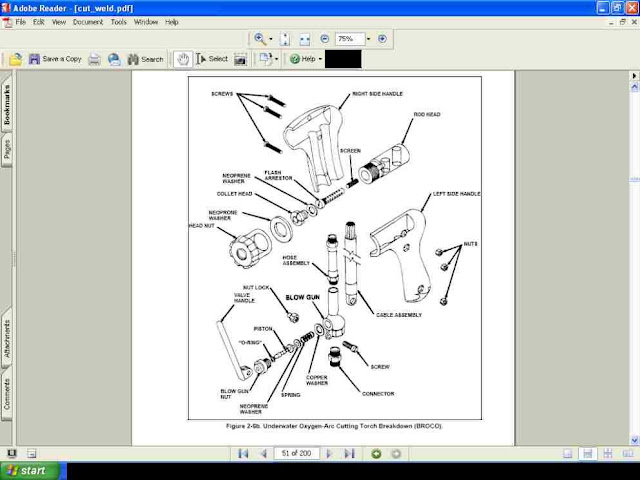

4-2.7 Underwater Oxygen-Arc Cutting Torches................................................... 4-17

4-3 EQUIPMENT FOR UNDERWATER SHIELDED METAL-ARC WELDING .................................................................................................. 4-19

4-3.1 Electrode Holders ....................................................................................... 4-19

4-4 WELDING ACCESSORIES ....................................................................... 4-20

Appendix Page

DOCUMENTATION MATRIX

A-1 PURPOSE..................................................................................................... A-1

A-2 REFERENCE DOCUMENTS...................................................................... A-1

METRIC CONVERSION FACTORS

English and Metric Equivalents .......................................................................................B-1

Weights ...................................................................................................................B-2

Measures .................................................................................................................B-2

Pressure or Stress (Force/Area) .......................................................................................B-3

Temperature Conversion..................................................................................................B-3

Metric Prefixes.................................................................................................................B-3

Multiplication Factors......................................................................................................B-3

C BIBLIOGRAPHY..........................................................................................................C-1< br> D SAFETY IN UNDERWATER CUTTING AND WELDING

D-1 PURPOSE..................................................................................................... D-1

D-2 GENERAL.................................................................................................... D-1

D-3 EXPLOSIVE GASES................................................................................... D-1

D-3.1 General Information...................................................................................... D-2

D-3.2 Specific Information ..................................................................................... D-2

D-4 ELECTRICITY UNDERWATER................................................................ D-4

D-5 GENERAL PRECAUTIONS FOR UNDERWATER CUTTING AND WELDING.................................................................................................... D-4

D-6 POWER SUPPLY......................................................................................... D-5

D-7 ELECTRODE HOLDERS AND CUTTING TORCHES ............................ D-6

D-8 POWER CABLES AND CONNECTORS................................................... D-7

D-9 SAFETY SWITCH....................................................................................... D-8

D-10 FIRE AND EXPLOSION PREVENTION................................................... D-9

D-10.1 Major Causes .............................................................................................. D-10

D-11 COMPRESSED GAS SUPPLIES .............................................................. D-10

D-11.1 Use, Handling and Storage of Compressed Gases...................................... D-10

D-11.1.1 The Never List ............................................................................................ D-10

D-11.1.2 The Always List.......................................................................................... D-11

D-11.1.3 General Oxygen Precautions ...................................................................... D-12

D-11.1.4 General MAPP Gas Precautions ................................................................. D-12

D-11.2 Additional Safety Precautions .................................................................... D-13

D-12 PERSONAL SAFETY IN DIVING ........................................................... D-14

D-12.1 Diving Dress ............................................................................................... D-14

D-13 CONCLUSION........................................................................................... D-14

E EXCEPTIONAL SITUATIONS

E-1 PURPOSE......................................................................................................E-1

E-1.1 Discussion......................................................................................................E-1

E-1.2 Authorization .................................................................................................E-1

E-2 UNDERWATER CUTTING EQUIPMENT.................................................E-1

v E-2.1 Arcwater Cutting............................................................................................E-1

E-2.2 Principles of Operation ..................................................................................E-2

E-2.3 Applications ...................................................................................................E-2

E-2.4 Necessary Equipment ....................................................................................E-2

E-2.4.1 Power .............................................................................................................E-2

E.2.4.2 Water..............................................................................................................E-2

E-2.4.3 Arcwater torch ...............................................................................................E-2

E-2.4.4 Electrodes.......................................................................................................E-2

E-2.5 Arcwater Electrode Cutting Technique .........................................................E-4

E-2.5.1 Underwater Preparations................................................................................E-4

E-2.5.1.1 Cutting ...........................................................................................................E-4

E-2.5.1.2 Gouging .........................................................................................................E-4

E-2.6 Material Consumption ...................................................................................E-5

E-2.7 Post-Dive Maintenance..................................................................................E-5

E-3 CUTTING UNDERWATER WITH THERMIC LANCE (BURN BARS)............................................................................................................E-5

E-3.1 Material Description ......................................................................................E-7

E-3.2 Required Equipment ......................................................................................E-8

E-3.3 Set Up Procedure ...........................................................................................E-8

E-3.4 Material Consumption ................................................................................ E-10

E-4 MAPP GAS CUTTING...............................................................................E-10

E-4.1 Principles of Operation ................................................................................E-10

E-4.2 Equipment and Material...............................................................................E-11

E-4.3 Protective Clothing ......................................................................................E-12

E-4.4 Cylinders and Regulators.............................................................................E-12

E-4.4.1 Purging the Hoses ........................................................................................E-12

E-4.5 Underwater MAPP Gas Cutting Torches.....................................................E-14

E-4.6 Igniting the Torch Above Water..................................................................E-16

E-4.6.1 Preparation ...................................................................................................E-16

E-4.6.2 Ignition.........................................................................................................E-16

E-4.7 Lowering the Ignited Torch .........................................................................E-18

E-4.8 Underwater Cutting......................................................................................E-18

E-4.8.1 Starting the Cut at the Edge of a Plate .........................................................E-18

E-4.8.2 Starting the Cut at the Central Portion of a Plate.........................................E-18

E-4.8.3 Advancing the Cut .......................................................................................E-21

E-5 UNDERWATER WELDING......................................................................E-22

E-5.1 Waterproofing Surface Electrodes...............................................................E-22

E-5.2 Preparation for Underwater Shielded Metal Arc Welding ..........................E-24

E-6 LOSS OF VOICE COMMUNICATIONS ..................................................E-26

E-7 FRICTION STUD WELDER......................................................................E-26

E-7.1 Principle of Operation..................................................................................E-26

E-7.2 Advantages...................................................................................................E-26

E-7.3 Equipment Requirements.............................................................................E-27

E-7.3.1 Equipment Details........................................................................................E-27

Glossary ............................................................................................. Glossary-1

Index ....................................................................................................... Index-1

LIST OF ILLUSTRATIONS

2-1 Underwater Oxygen-Arc Cutting Electrodes................................................................... 2-3

2-2 Underwater Oxygen-Arc Electrode Designs ................................................................... 2-4

2-3 Drag Techniques for Cutting Steel with Steel-Tubular Electrodes ............................... 2-12

2-4 Technique for Cutting Steel Less Than 1/4 Inch with Steel-Tubular Electrodes .......... 2-16

2-5 Technique for Piercing Holes in Steel Plate using the Oxy-Arc Process with Steel Tubular Electrodes................................................................................................ 2-17

2-6a Underwater Oxygen-Arc Cutting Torch Breakdown (Arcair)....................................... 2-19

2-6b Underwater Oxygen-Arc Cutting Torch Breakdown (BROCO) ................................... 2-20

2-6c Underwater Oxygen-Arc Cutting Torch Breakdown (Craftsweld) ............................... 2-21

2-7 Technique for Cutting Steel Using Exothermic Electrode ............................................ 2-29

2-8 Seeler Kerie Cable Control Panel ................................................................................. 2-36

2-9 Typical Kerie Cable Set Up ........................................................................................... 2-38

2-10 Technique for Underwater Shielded Metal-Arc Cutting of Thick Plate and Round Stock................................................................................................................... 2-47

3-1 Test Specimen for Tee Fillet Weld .................................................................................. 3-5

3-2 The Underwater Welding Arc.......................................................................................... 3-9

3-3 Parts of a Weld............................................................................................................... 3-11

3-4 Self-Consuming Technique for Underwater Shielded Metal Arc Welding of Horizontal Fillet Welds ............................................................................................. 3-16

3-5 Self-Consuming Technique for Underwater Shielded Metal Arc Welding of Vertical Fillet Welds.................................................................................................. 3-18

3-6 Technique for Underwater Shielded Metal Arc Welding of Overhead Fillet Welds.................................................................................................................... 3-19

3-7 Feeding-In Technique for Underwater Shielded Metal Arc Welding of Fillet Welds in Wide-Gap Joints.................................................................................... 3-21

3-8 Repair Method for Cracks in Underwater Structures Using a Rectangular Patch......... 3-23

3-9 Repair Methods for Cracks in Underwater Structures Using a Circular Patch.............. 3-24

3-10 A Typical Underwater Welding Electrode Holder ........................................................ 3-26

4-1 Typical Arrangement of Underwater Arc Cutting Equipment ........................................ 4-2

4-2 MK12 SSDS Welding Shield .......................................................................................... 4-3

4-3 MK1, MOD 0 Mask and Lens Holder Assembly ............................................................ 4-4

4-4 Superlite-17B/NS Helmet and Lens Holder Assembly ................................................... 4-5

4-5 MK 12 Helmet Lens Holder Assembly with Parts Identification.................................... 4-6

4-6 Superlite-17B/NS Welding Lens Holder with Parts Identification ................................. 4-7

4-7 Typical Welding Generator and Power-Converter Control Panel ................................. 4-10

4-8 Equipment Arrangement for Welding and Cutting Straight Polarity ............................ 4-12

4-9 Tong Test Ammeter ....................................................................................................... 4-14v 4-10 Voltage Drop in Welding Cables................................................................................... 4-18

E-1 Arcwater Torch Assembly ...............................................................................................E-3

E-2 Thermic Lance Holder Assembly ....................................................................................E-9

E-3 Standard Thermic Lance Equipment Set Up ...................................................................E-9

E-4 Standard Surface Cutting Torch with Underwater Spacer Sleeve.................................E-15

E-5 Starting the Cut at the Edge of a Plate ...........................................................................E-19

E-6 Starting a Cut in the Central Portion of a Plate..............................................................E-20

E-7 Restarting the Cut ..........................................................................................................E-21

E-8 Friction Stud Welder......................................................................................................E-28

LIST OF TABLES

2-1 Cutting Amperage Requirements for Steel-Tubular Electrodes ...................................... 2-6

2-2 Oxygen Regulator Settings for Oxygen-Arc Cutting Electrodes (Hose Lengths 50 Foot and 200 Foot)...................................................................................................... 2-7

2-3 Material Consumption using Steel-Tubular Electrodes................................................. 2-10

2-4 Recommended Power Settings for Cable Length/Size for Ultrathermic Electrodes ....................................................................... 2-24

2-5 Exothermic Electrode Consumption Guide ................................................................... 2-26

2-6 Oxygen Regulator Settings for Kerie Cable Cutting ..................................................... 2-41

2-7 Kerie Cable Size/Metal to be cut ................................................................................... 2-42

2-8 Kerie Cable Oxygen and Cable Consumption Ratio ..................................................... 2-42

2-9 Material Requirements for Underwater Shielded Metal-Arc Cutting ........................... 2-45

3-1 Guide to Steels and Electrodes for Wet Welding ............................................................ 3-4

3-2 Electrodes for Underwater Shielded Metal Arc Welding................................................ 3-7

3-3 Recommended Amperage Settings for Wet Welding to Depths of 50 Feet .................... 3-7

4-1 Recommended Equipment for Underwater Arc Cutting and Welding............................ 4-8

4-2 Equipment Load-out for Wet Cutting/Welding Operations .......................................... 4-22

4-3 List of Manufacturers..................................................................................................... 4-26

4-4 Parts Information ........................................................................................................... 4-28

A-1 Salvage Documentation Matrix ...................................................................................... A-2

E-1 Arcwater Operating Data Cutting Carbon Steel ..............................................................E-6

E-2 Equipment and Material Requirements for Underwater MAPP Gas Cutting ........................................................................................................E-11

E-3 Regulator Gauge Settings ..............................................................................................E-13

E-4 Recommended Cutting Tip Sizes ..................................................................................E-14

E-5 Recommended Pressure Settings and Hose Size Selection Chart .................................E-17

E-6 Surface Welding Electrodes Suitable for Wet Welding ................................................E-23

E-7 Recommended Amperage Settings for Wet Welding to Depths of 50 FSW.................E-25

DON'T BE CONFUSED BY OTHER CD MANUALS!

LOW RESOLUTION Sample image From Adobe Acrobat Viewer (included on CD)

Actual CD images are higher resolution and clarity

.............................................................................

see ad description:

Payment and Shipping Details

Seller IP Address:

- United States

- United States Shipping services available:

| Shipping / Handling Cost | Cost For Each Additional Item | Service |

|---|---|---|

| $5.00 | $0.00 | Standard Shipping (1 to 5 business days) |

Payment methods accepted:

Check or Money Order

Check or Money Order

Return Policy:

Returns are not Accepted